Stitch

Stitch

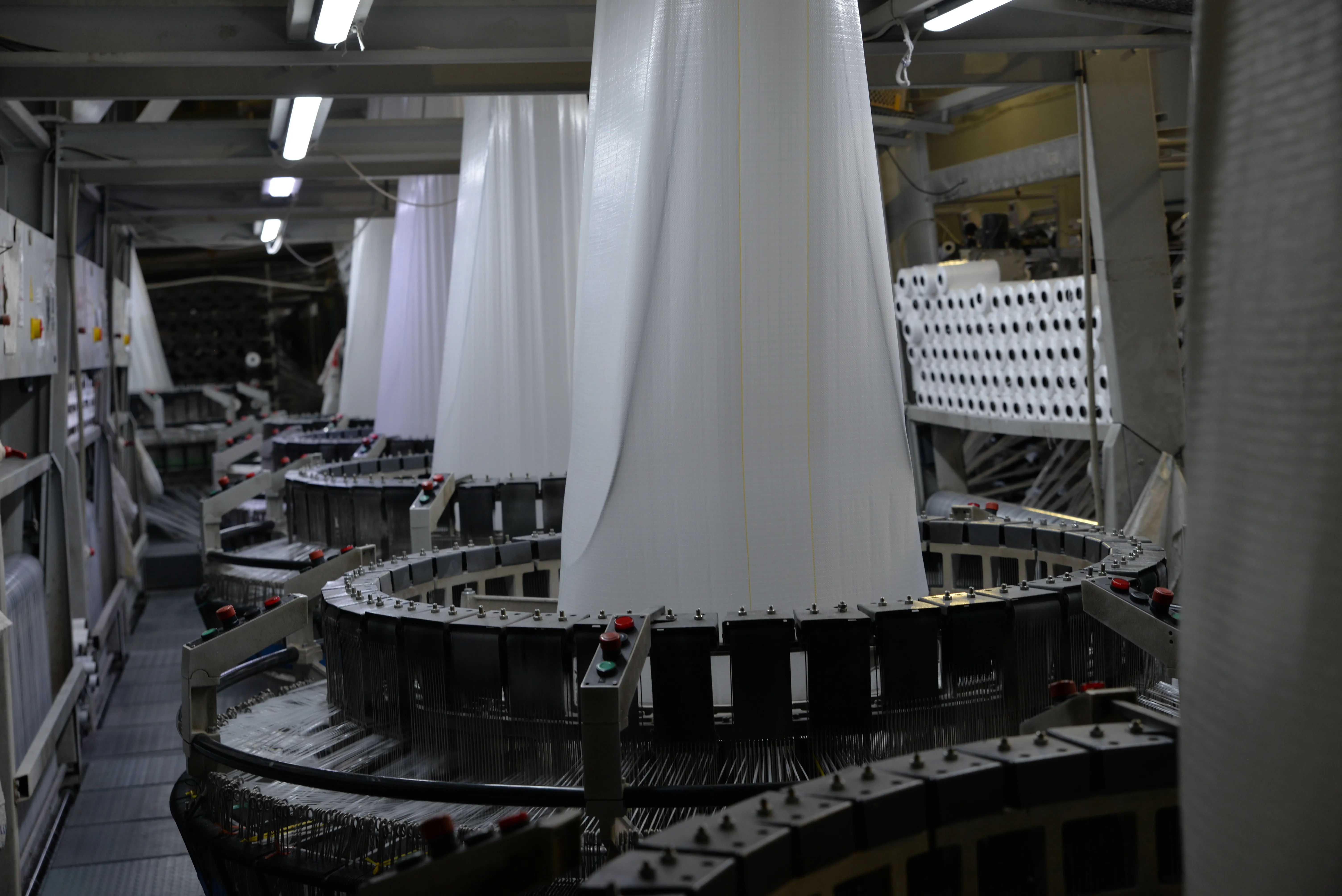

Standard stitching is one of the core production steps that completes Özdal Group’s packaging and technical textile solutions. Especially for sacks, bags, roll-based materials and various packaging formats, we provide a high and stable seam quality that is compatible with your filling and handling processes.

In our production, we use single-needle and double-needle chain stitch / lock stitch systems designed for PE/PP woven fabrics, laminated surfaces and multilayer structures. This allows us to control seam consistency, sealing performance and mechanical strength for both standard loads and relatively higher load-carrying applications.

Key features of our Standard Stitching service:

Repeatable quality: Identical seam parameters for the same product and same line, batch after batch.

Proper yarn selection: Yarn quality and thickness selected according to the usage conditions and load profile.

Optimized seam geometry: Stitch density, pitch and edge distance are adjusted to the specific product.

Line efficiency: Automatic and semi-automatic feeding options for fast and balanced production.

Clean appearance & brand image: Neat seams also support perceived product and brand quality.

Within our quality control workflow, we perform seam strength tests, opening checks under load and visual inspections. When necessary, process parameters (speed, stitch length, yarn tension, etc.) are fine-tuned. On request, we can also develop tailor-made solutions for different applications such as bottom seams, mouth/closure stitching and side seams.

In short, with our Standard Stitching service, your packaging is not only closed — it is made reliable, line-friendly and ready to withstand transport and storage conditions.