PE Ekstrüzyon

PE Ekstrüzyon

PE (Polyethylene) extrusion is the process of melting polymer granules under heat and pressure in a screw extruder and shaping them along a continuous production line. Once the material becomes molten, it is pushed through a die, cooled, and then wound, cut, or slit to the desired dimensions.

In short: “melt, shape, cool, and wind”—the pasta machine of the plastics world. 🍝

Materials Used

LDPE (Low-Density PE):

Soft, transparent, good sealability; used for flexible packaging films.LLDPE (Linear Low-Density PE):

High tensile and puncture resistance; used for stretch film and load-holding applications.HDPE (High-Density PE):

Rigid, chemically resistant; used for pipes, jerrycans, carrier films, and coatings.Optional additives:

Masterbatch (color), UV stabilizers, slip/antiblock agents, antistatic additives, recycled material blends.

Main Steps of the Process

Feeding & Melting:

Granules are melted along the screw at around 160–230 °C (depending on grade and MFI).

Screw L/D ratio is typically 24:1–34:1.Homogenization & Pressure Build-Up:

The melt is homogenized by screw flights and mixing elements; melt pressure and temperature are monitored via sensors.Die (Kalıp) Design & Shaping:

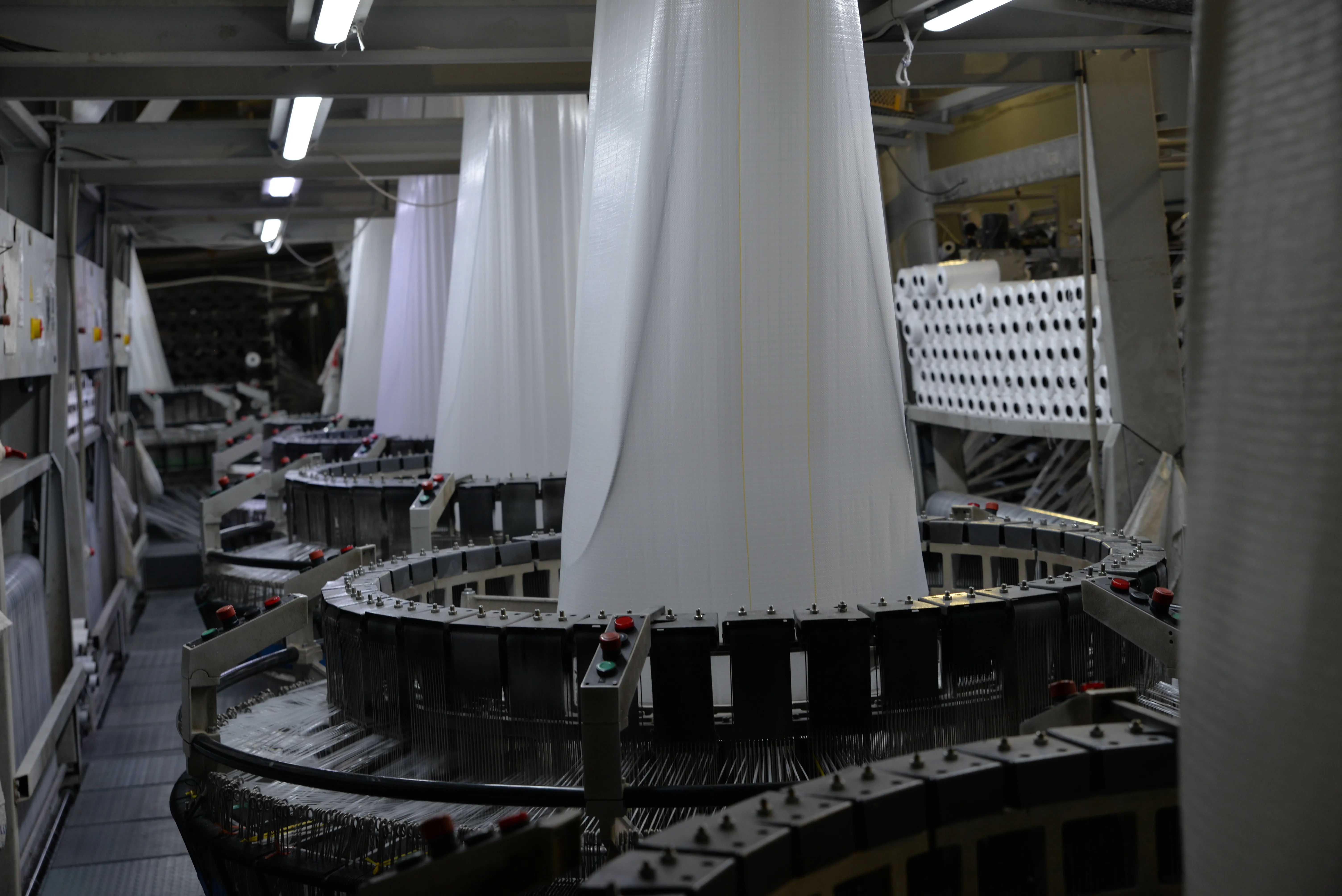

Circular die (blown film): Film formed by bubble inflation.

Flat die (cast): Film/sheet cast onto a chill roll for high optical quality and flatness.

Pipe/Profile die: For HDPE pipes and special technical profiles.

Coating die: Extrusion coating/lamination of melt onto paper or aluminum.

Cooling & Sizing:

Using water baths, air rings, or chill rolls to stabilize dimensions and surface quality.Haul-Off, Edge Trimming & Winding:

Line speed and draw-down ratio (BUR, draw ratio) control thickness and mechanical properties. Edge trimming and winding define final roll format.

Types of Extrusion

Blown Film Extrusion:

More balanced mechanical properties in MD/TD, lower investment cost; used for packaging films, bags, shrink films.Cast Film/Sheet Extrusion:

Better optics and thickness tolerance; used for laminations and barrier structures.Pipe/Profile Extrusion:

HDPE pipes for water/gas lines, cable conduits, technical profiles.Extrusion Coating & Laminating:

PE coating on paper/foil; e.g. milk cartons, various food packages.Co-Extrusion:

Multilayer structures (e.g. PE/tie/EVOH/tie/PE) to achieve barrier and adhesion properties.

Advantages

High output and continuity:

Long, uninterrupted production runs.Cost-effectiveness:

Efficient in both energy and material usage; can incorporate recycled material.Wide application range:

Packaging, pipes, wire & cable, agricultural films, construction membranes.Chemical and moisture resistance:

Suitable for food contact and outdoor conditions (with proper formulation).

Typical Applications

Packaging:

Shopping bags, carrier films, shrink films, stretch films, vacuum pouches.Infrastructure:

Potable water and gas HDPE pipes, drip irrigation laterals.Electrical:

Cable jacketing and semiconductive layers (with suitable compounds).Industrial:

Pallet covers, construction sheeting, membranes.

Quality Parameters (Example)

Thickness tolerance: Typically ±5–8 %, depending on process and film width.

Width tolerance: Typically ±2–5 mm.

MFI (190 °C/2.16 kg):

For films usually 0.3–4 g/10 min; for pipes lower MFI grades are preferred.Optical properties: Haze, gloss, gel/fish-eye count.

Mechanical properties: Tensile strength, elongation, dart drop impact, tear resistance.

Food contact: Compliance with relevant regulations (e.g. EU 10/2011) must be declared.

Process Tips

Moisture and dust control:

PE is non-hygroscopic, but dust and contamination impair surface quality; use drying/sieving if needed.Temperature profile:

Lower MFI (higher viscosity) grades require higher temperature/pressure; avoid thermal degradation.Thickness control:

Automatic thickness gauges and air rings (IBC) significantly improve thickness uniformity.Recycling:

Regrind usage typically 10–50 %, adjusted according to end-use performance requirements.